Billet vs. Forged Lower Receivers (Yes, One is Better)

Posted by Gunbuilders.com on Jun 9th 2025

We sell a lot of AR-15 jigs and AR build kits. So, we're f requently asked which lower receiver's better for building an AR: Billet or forged? Plenty of builders will tell you that it's entirely up to personal preference -- that both types of lowers are basically identical when it comes to performance.

That's simply not true. Each lower has its unique pros and cons and one is, generally, simply "better" overall.

Billet & Forged: What's Different?

Billet and forged lowers vary in two ways: What they're made of, and how they're made.

Forged lowers are, as their name implies, forged from 7075-T6 aluminum. To make 'em, a bucket of alloy is heated until liquid, then poured into molds containing one half of the rough shape of the receivers. Large steam- or hydraulic-powered hammers are fitted with the other halves of the receivers' shapes.

The receivers are pressed into their rough shapes when struck by the hammers to create forgings. The rough forgings are then cut into their final shapes inside CNC machines.

Billet lowers are made from blocks of extruded 6061-T6 aluminum. These receivers are simply cut into their final shapes by CNC machines.

Forged Lower Advantages

Forged lowers are stronger than billet lowers. They're also physically smaller and usually lighter. This is because the forging process both compacts the aluminum into a denser, harder shape and it aligns the crystalline structure of the metal, promoting stronger bonds between the metal's molecules that result in higher overall strength.

Forged lowers are also more affordable. This is partly because they require less machining than billet lowers, and partly because they're produced in far greater numbers by more manufacturers, which further lowers production costs (pun intended).

Forged Lower Disadvantages

There are few to no disadvantages in choosing a forged lower. It is possible that, in very rare circumstances, a forged lower's final dimensions and tolerances may be off. This can result in other components becoming misaligned once installed, like the buffer tube (due to the tube's housing's threads being off-center) or upper receiver (because of poorly struck pivot pin and rear takedown pin mounts).

But these imperfections are virtually nonexistent in today's high-volume, long-perfected process of manufacturing forged receivers. And in the rare case you wind up with an out-of-spec forged lower, it's all but guaranteed to be warrantied against craftmanship errors and manufacturing defects.

What's more, the finishing process these receivers undergo in CNC machines virtually eliminates any small imperfections that might've been present in the rough forging.

Billet Lower Advantages

With how seemingly perfect forged lowers are, it's important to note that billet lowers are still popular, and for good reason. Their extruded and CNC-cut manufacturing process ensures all dimensions, mounts, holes, and threaded fittings are virtually perfect, with tolerances usually as small as a few thousands of an inch, if not just a few microns.

Billet lowers also tend to just look cool. Since they're cut from blocks of prefabricated aluminum, they can be made into more complex shapes. Most billet lowers are also fitted with extra features, like integrated trigger guards (which make assembly easier, and add to the strength of the receiver) and threaded fittings that replace the old-school (and more difficult to assemble) roll pin and spring-and-plunger fittings found on forged lowers.

Billet Lower Disadvantages

Although they are, for all practical purposes, just as strong as forged lowers, billet lowers do suffer some small disadvantages: They're usually more expensive, they have a lower surface hardness (which makes their finishes easier to dent and scratch) and, depending on their final cut dimensions, they could be incompactible with certain upper receivers and other components (though this is quite rare).

So, Which Lower's Better?

If you're looking to build the most reliable and strongest AR-15, and if you want to do it for the lowest price possible, stick with the tried n' true forged lower receiver. These receivers are stronger, smaller, and they're guaranteed to work with virtually AR-15 part.s They're also so widely produced that encountering any imperfections in their fitment or finish is exceedingly rare.

But if you want to build the nicest- and cleanest-looking AR-15 with some extra features and aesthetic points, and if you want to have an easier time assembling your AR from scratch, a billet lower is a better choice.

Which 80% Lower's Easier to Machine?

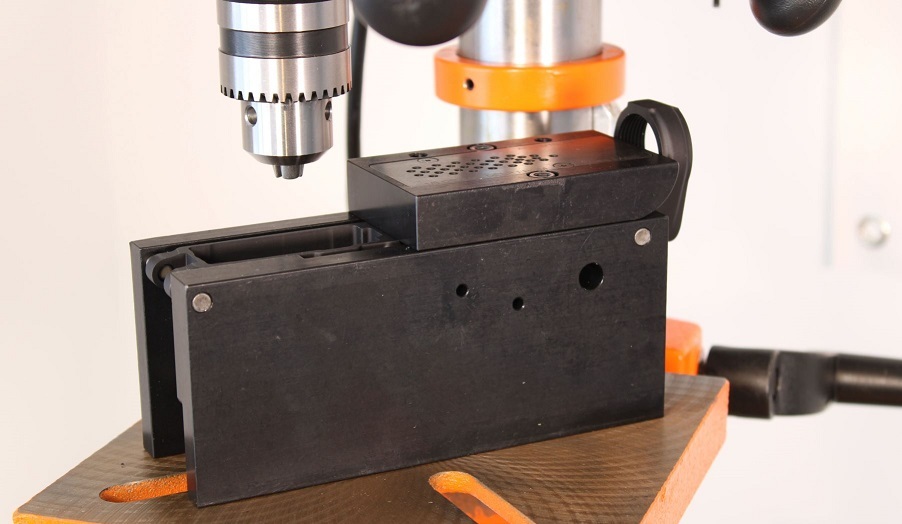

Pictured: Elite Builder Jig for AR-15/AR-9

Since we do sell 80% jigs for the AR-15, it's only appropriate we answer the question: Billet 80% lowers are easier to cut and drill at home than forged 80% lowers. The billet lower's surface hardness inflicts less wear and tear on end mill bits and drill bits, and it's 6061-T6 aluminum is easier to cut and drill into using lower torque, "DIY enthusiast" power tools and equipment.

DISCLAIMER: If you are new to the world of DIY gun building, you likely have a lot of questions and rightfully so. It’s an area that has a lot of questions that, without the correct answers, could have some serious implications. At GunBuilders.com, we are by no means providing this content on our website to serve as legal advice or legal counsel. We encourage each and every builder to perform their own research around their respective State laws as well as educating themselves on the Federal laws. When performing your own research, please be sure that you are getting your information from a reliable source.