The Full Guide to the AR-15 Bolt Carrier Group

Posted by Gun Builders Depot on Sep 13th 2019

Full auto! "M16 BCG". Staked gas keys - what does it all mean? Today, we're teaching you everything you could ever want to know about the AR-15 bolt carrier group. This guide will break down its functionality, how it works as part of the black rifle's gas system, what types of BCGs are out there, and of course, what the difference is (really) between a "full-auto" BCG and a regular commercial unit.

What is The Bolt Carrier Group?

The AR-15 bolt carrier group (called the "BCG)") is the part of the rifle or pistol that's responsible for performing semiautomatic fire when the trigger is pulled, with a series of steps in this order:

- Allowing the firing pin to strike the primer on the chambered round.

- Grabbing and ejecting the spent shell casing from the fired round.

- Re-cocking the hammer in the lower receiver for the next round.

- Grabbing a new round from the magazine and chambering it.

These four actions are automatically performed when the shooter pulls the trigger. The act of chambering a new round and cocking the hammer allows the cycle to repeat, eliminating the need for a manual bolt or single-shot configuration.

The AR-15's BCG is considered a locking, rotating bolt mechanism. That means the bolt itself is "locked" inside the firing chamber. It only cycles when sufficient pressure has built up, forcing the bolt to rotate and unlock. We'll explain how this works in greater detail:

How the BCG Works

The bolt carrier group performs all these tasks by harnessing the gas produced by the round being fired. A gas tube connects a gas port on the barrel to the gas /carrier key atop the BCG. This key forces all that high-velocity gas into the body of the BCG. When this happens, the BCG unlocks and drives backward into the buffer tube, compressing the buffer and buffer spring. The compressed buffer spring re-expands rapidly, driving the BCG back into the upper receiver. As the animation shows, the spent casing is ejected and a new round is chambered when this happens. This entire process takes less than one second, making it way more efficient than a bolt-action rifle.

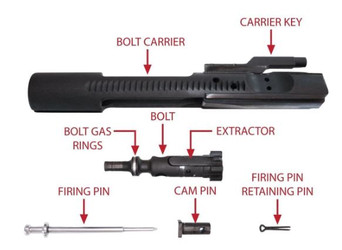

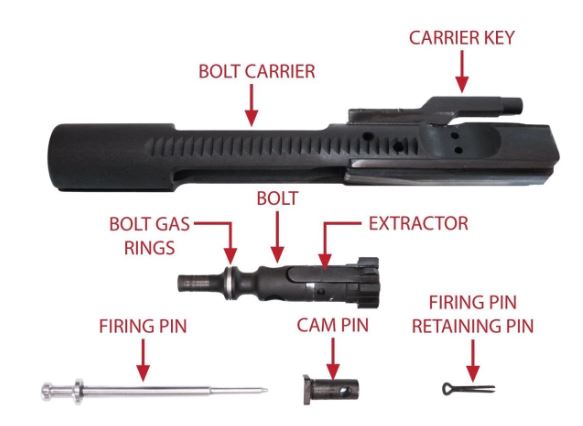

Diagram: The BCG Explained

To accomplish semiautomatic fire, the BCG has to perform many actions. Although the animation makes the BCG appear as one solid unit, there are numerous components that must all move and work together in rapid succession to allow for rapid semi-auto fire. If you want to know how the locking bolt works, keep reading.

Let's break down each piece and what it does:

Bolt Carrier

This is the "meat" of the BCG. It's the primary housing that contains all the other important stuff: The firing pin, gas key, cam pin, extractor, and bolt. The bolt carrier is what contacts the buffer and spring. It also absorbs a ton of force as gas expands inside the carrier. To handle this pressure and heat safely, the bolt and carrier are made from three types of forged steel: Carpenter no. 158, 8620, or 9310. Don't worry, we'll explain these three types of steel later.

Gas / Carrier Key

The gas key (also called a carrier key) is the small protrusion atop the bolt carrier that harnesses the gas coming out of the gas tube. The key is hollow, allowing gas to pass through it and into the body of the bolt carrier, where the bolt and extractor are located. Importantly, it is this passing of gas (no pun intended) that forces the bolt and extractor to rotate, locking and unlocking the carrier group from the firing chamber.

Bolt & Extractor

The bolt and extractor perform their own functions, but they work simultaneously as one unit. The rotating bolt itself features a "star" at the front, shaped like a cog, which allow the BCG to lock and unlock inside the AR-15's star chamber. It rotates approximately 15 degrees to lock and unlock inside the chamber. The extractor hooks the rim of each round, capturing it and pulling it out of the star chamber after firing. At the same time, a small ejector and spring inside the head of the bolt itself puts pressure on the casing. As the casing exits the chamber, the ejector's spring forces the spent casing to exit the upper receiver as the BCG flies back into the buffer tube. The carrier and bolt then ride forward, allowing the bolt head and extractor to grab another round.

Bolt Gas Rings

The small gas rings shown on the bolt in the diagram above are designed to trap the expansion of gas, allowing it to operate the bolt instead of just dispersing inside the upper receiver.

Firing Pin & Retaining Pin

The firing pin rests inside the bolt itself. The head of the pin just barely protrudes from the head of the bolt, next to the ejector. As the hammer is released by the trigger, it flies up into the carrier and hits the back of the pin. The head of the pin then strikes the primer of the round being held by the head of the bolt, firing it. The firing pin must be able to freely move back and forth inside the BCG so it has enough action to strike the primer, but this would allow the pin to fall out if it weren't limited. To prevent the firing pin from slipping out of the bolt as the BCG rides forward, a small retaining pin is inserted through the side of the carrier.

Cam Pin

The cam pin is what prevents the bolt from rotating too much when it unlocks. The cam pin is inserted through the carrier, into a hole in the bolt. A cut-out atop the carrier provides a channel for the cam pin to ride back and forth. The cam pin also has a hole in the middle of it for the firing pin to slide through. This ensures the cam pin is correctly oriented and doesn't fall out. It also keeps the cam pin, bolt, and firing pin rotating and moving as one unit.

"M16" & Full-Auto vs. Commercial BCGs

First, let's break up a myth: Installing an M16 or "full-auto" BCG in your AR-15 won't transform it into an automatic rifle (which would be incredibly illegal, anyway). Transforming a semiautomatic AR-15 into a fully-automatic rifle would require swapping out the trigger, disconnector, hammer, and safety selector lever. Commercial lower receivers also don't have the internal space fabricated to allow for these different automatic parts to be installed. Both full-auto and commercial BCGs perform exactly the same. They use the same parts, too. The only difference is the physical dimensions of the carrier itself.

The fatter portion located on the rear of the M16 BCG allows it to work with an auto sear. The M16's auto sear works by allowing the full-auto bolt to lock and unlock continuously, cycling rounds while the trigger remains depressed. Without getting into the technical details, the auto sear needs that extra piece of steel on the bottom of the M16 bolt to function. Without it, the auto sear can't be "tripped", thus allowing the hammer to cock and de-cock (firing rounds automatically) without pulling the trigger every time.

"Is using an M16 bolt illegal?"

Nope! Not at all. Using an M16 or full-auto BCG in any AR-15 is 100% legal. They are not regulated by any laws, whatsoever. Owning an M16 BCG won't land you in hot water with the feds or the ATF, either. The same can't be said if you were to buy an auto sear and full-auto parts kit, though.

BCG Steel Types Compared

If you're shopping around for a BCG, you've probably come across those three types of steel mentioned earlier: Carpenter No. 158, 8620, and 9310. Let's compare them but first, let's explain tensile and yield strength. Tensile strength is the maximum stress an object can withstand without stretching. Yield strength measures how much force must be exerted on something before it permanently deforms.

Carpenter No. 158 Bolt Steel

Carpenter No. 158 steel is the mil-spec steel used for fabricating the bolt itself. This type of steel is more expensive than 9310 (another popular steel used for the bolt and carrier), but it provides the best performance and lifespan for the BCG. C158 steel is a proprietary type of steel developed for the U.S. Military by Carpenter Technology. Because it's proprietary, the manufacturer only sells it in large batches annually. This is why BCGs advertising Carpenter 158 steel are typically made by the "big name" companies like FN, Colt, and Daniel Defense.

C158 is case- (or surface-) hardened. This means the exterior of the steel is made to be very hard, preventing cracking and surface wear. Inside, the steel is softer and more flexible, preventing deformation and stress fractures.

- Tensile Strength: 1103 MPa

- Yield Strength: 931 MPa

9310 Steel

9310 steel is used to make carriers and bolts simply because it is more readily available and cheaper to purchase. That's not to say this steel is inferior to Carpenter No. 158 - quite the contrary. C158 steel was originally developed in the 60's. Since then, advancements in metallurgy mean that 9310 steel, when fabricated and heat-treated correctly, may actually out-perform C158 steel.

- Tensile Strength: 910 MPa

- Yield Strength: 570 MPa

8620 Steel

This is the steel the U.S. Military uses for their "mil-spec" carriers. It's a relatively affordable steel that has performed admirably in full-auto M4s and M16s for decades. Because this steel provides lower tensile and yield strengths, it isn't generally used to manufacture bolts - just the carriers.

- Tensile Strength: 640 MPa

- Yield Strength: 360 MPa

Which steel is better?

For the average shooter, any of these steels will out-perform what you can put your AR-15 through.

Case-hardened Carpenter steel will perform best in extreme scenarios, such as during extended rapid fire or competition shooting. 8620 and 9310 steel are both through-hardened. This means the entire unit is heat-treated. Through-hardened steel can be softer and better at resisting shock, or harder and better at resisting wear (but not both, like C158).

What is "MPI" and "HPT"?

These are two other terms you've probably seen thrown around when looking at BCGs.

Magnetic Particle Inspected (MPI)

Bolt carrier groups are subjected to a lot of pressure, somewhere on the order of tens of thousands of pounds per square inch. If any part of the BCG suffers from microscopic cracks or fissures created during the manufacturing process, then firing a round with that BCG could result in a catastrophic failure (also see: "explode"). To ensure this doesn't happen, most BCGs undergo magnetic particle inspection.

To test for this, the BCG is placed inside a magnetic field, usually created with two electromagnets. A liquid solution containing magnetic particles is then applied to the steel. The magnetic particles will stick to any cracks, fissures, or tiny imperfections that are on or just under the surface. Ultraviolet light enhances the imperfections, making them visible to the naked eye. It's a wickedly cool process that you can see visualized by this MPI testing facility.

High-Pressure Testing (HPT)

High-pressure testing isn't as science-y as magnetic particle inspection, but it's still a critical requirement. This testing is completed by firing a high-pressure cartridge (well above the SAAMI-rated specifications for the cartridge in question) through the BCG being tested. This ensures the BCG is capable of handling repeat fire and extensive fun-button mashing.

Importantly, MPI testing is done after high-pressure testing. This ensures any cracks or deformities that would have been created by the end user firing the BCG are instead found before the unit ships out.

DISCLAIMER: If you are new to the world of DIY gun building, you likely have a lot of questions and rightfully so. It’s an area that has a lot of questions that, without the correct answers, could have some serious implications. At GunBuilders.com, we are by no means providing this content on our website to serve as legal advice or legal counsel. We encourage each and every builder to perform their own research around their respective State laws as well as educating themselves on the Federal laws. When performing your own research, please be sure that you are getting your information from a reliable source.