What is an 80% Lower Jig?

Posted by Gun Builders Depot on Aug 1st 2019

You know what an 80% lower is (if you don't, read this), and now you want to build your first gun using one. Whether that new gun is an AR or handgun, you need some tools to build it. Most tools are available around your house or at your hardware store, but one is specially made for the 80% lower you're fabricating. Tight tolerances are required, lest you wind up with a gun that's unreliable or dangerous. This would normally mean investing in an expensive CNC machine, but you don't need that. All you need is an 80% jig.

What's an 80% jig?

All 80% jigs provide the builder with the tools, measurements, and physical guides for fabricating an 80% lower or frame into a working firearm. Jigs are kits that consist of metal or plastic plates, bolts, and drill bits and end mill bits. Jigs are made specific to the firearm being built -- whether it's an AR rifle or pistol, or a handgun -- so parts and appearances vary. The most common type of jig is the AR-15 jig, like the Elite Builder. It's set up like most other AR jigs, so it makes a great example for the category.

AR-Type Jigs

AR-type jigs are used with billet, forged, and polymer AR-15, AR9, or LR-308 80% lowers. No matter which type of AR you're building, the steps required to finish the 80% lower are the same:

- Cut or mill the fire control cavity.

- Cut the trigger slot in the cavity's floor.

- Drill the hammer and trigger pin holes.

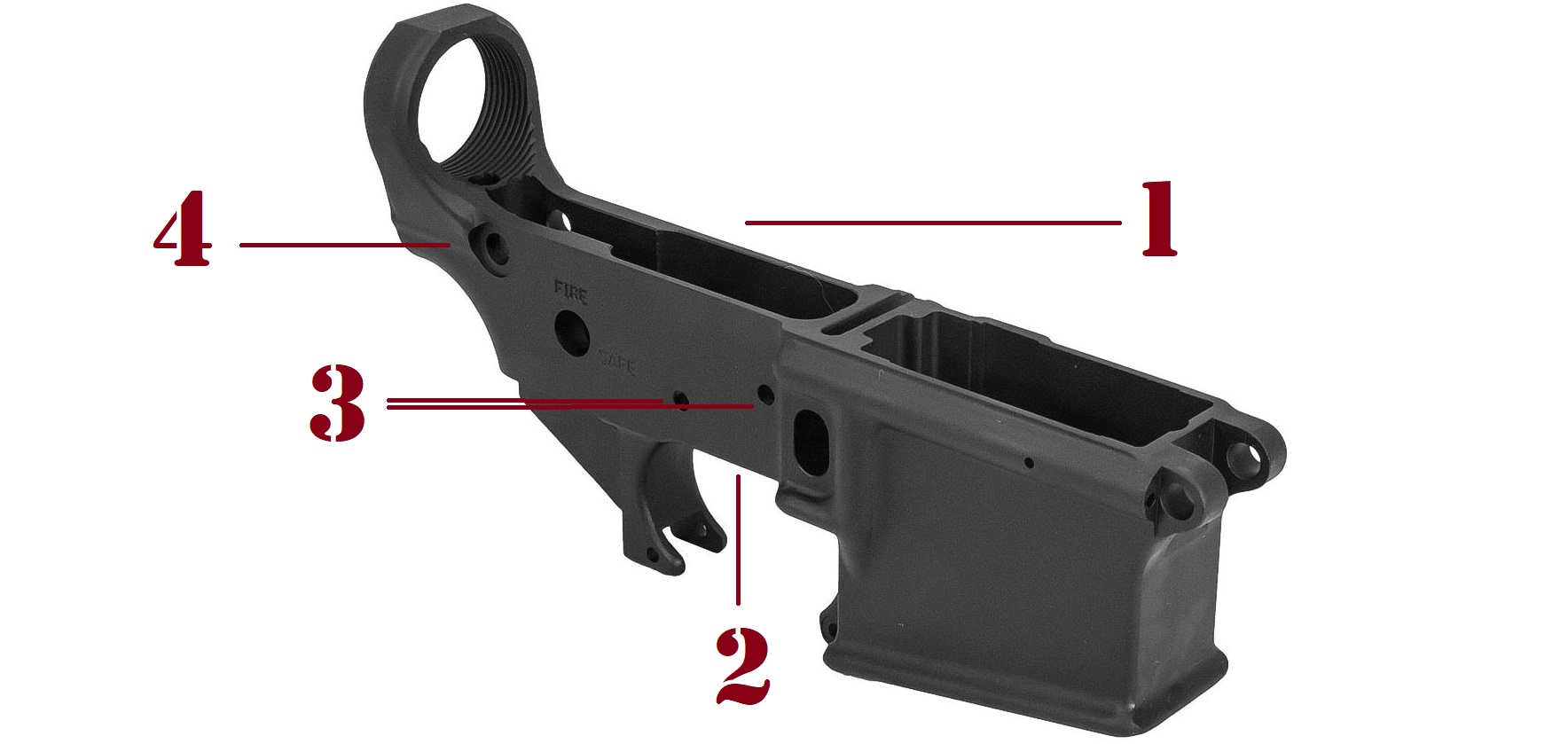

- Drill the safety selector lever pin hole.

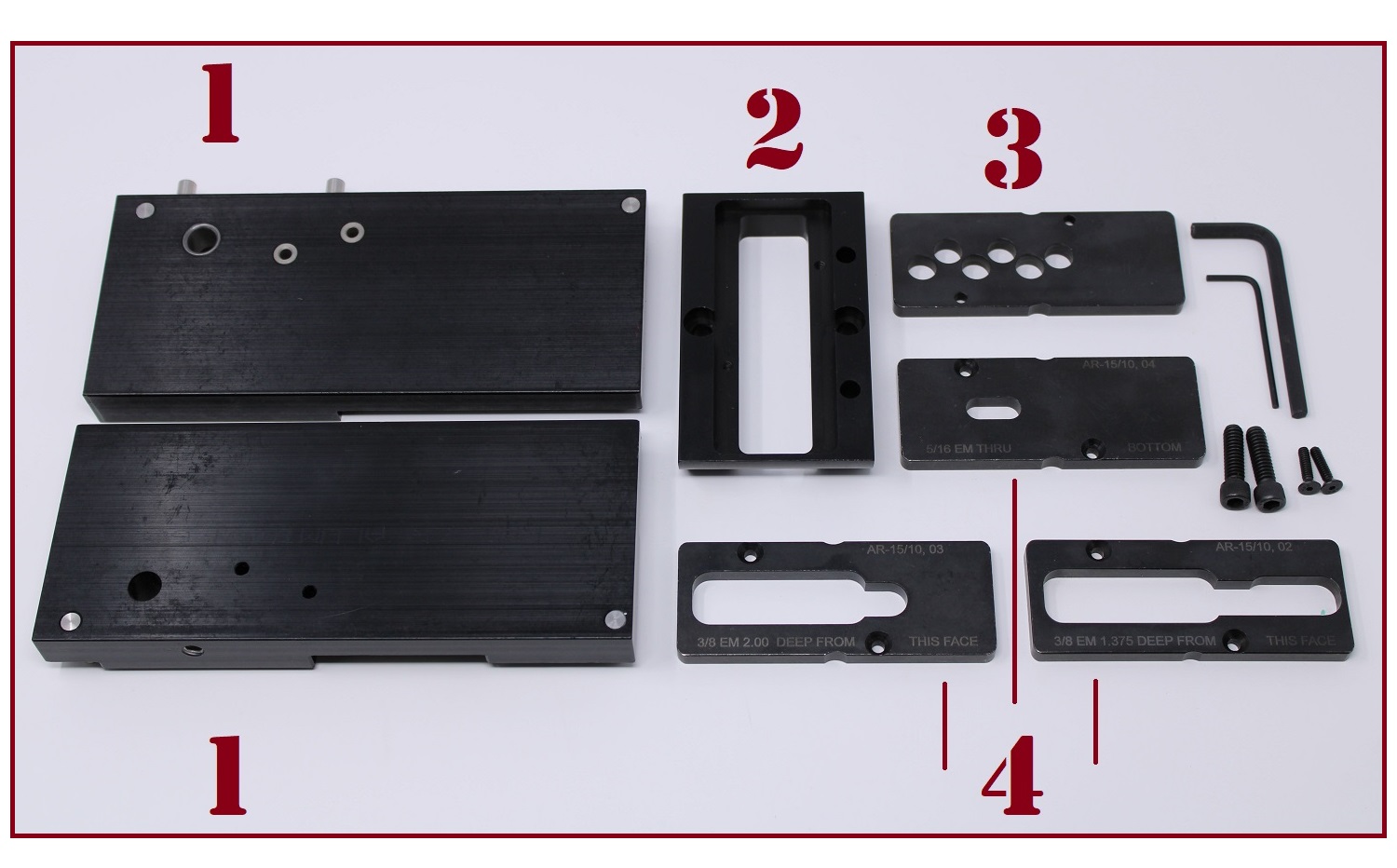

AR Jig Parts Diagram

1. Side Plates

The side plates clamp to either side of the 80% lower. These plates almost always have pre-drilled holes. The holes are guides for drilling pin holes for your AR's trigger, hammer, safety, and other functional items that will be installed in the lower receiver.

2. Template Holder

All AR jigs use templates. These templates are pre-shaped guides used to cut and drill the receiver to make room for those parts it needs to function. Often, a jig will use a base plate called a template holder to hold all these templates in place while you work. This ensures the placement of each template is consistent, relative to the position of the receiver.

3. Pilot Hole Template

Before the AR's receiver can be milled out inside, room needs to be made for the cutting end mill bit. One or more pilot holes will be drilled into the cavity to remove some of the aluminum and to make room for the cutting bit. Drilling more pilot holes reduces cutting/milling time and can extend end mill bit life, allowing you to complete more than one 80% lower with the original bits that came with your jig.

4. Cutting/Milling Templates

The cutting/milling templates guide the end mill bit around the cavity of the receiver while it cuts. You must control the feed rate and speed of the machine, as well as the cutting depth of the bit. Instructions tell you how deep to cut the receiver with each template and bit. With the receiver's cavity milled, a final template provides the shape for cutting the trigger slot.

5. Drill Bits & End Mill Bits

Shown in some of the parts' photos above, each AR jig comes with drill bits and end mill bits for fabricating the lower with your machine of choice, whether that's a drill press or milling machine. The drill bits are sized depending on the diameter of your AR's pin holes, while the end mill bits are typically sized based on the diameter of the cavity's pilot hole template.

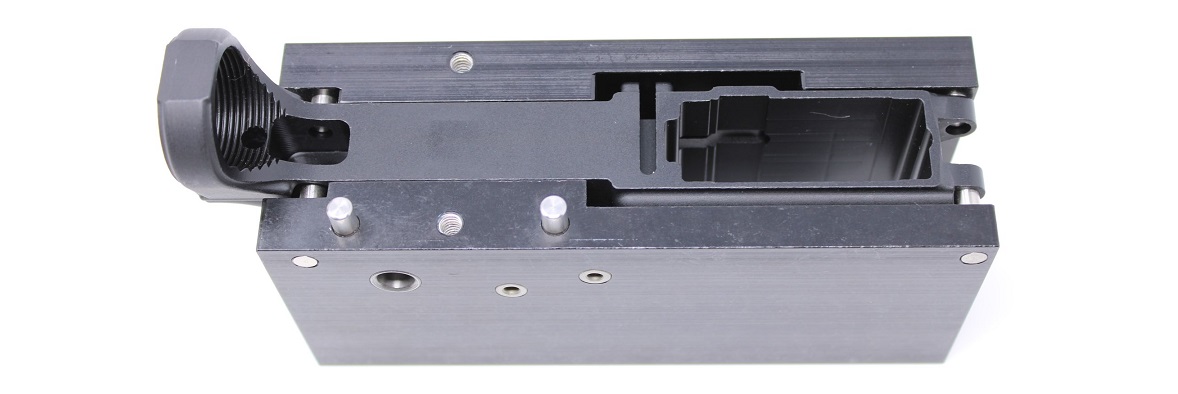

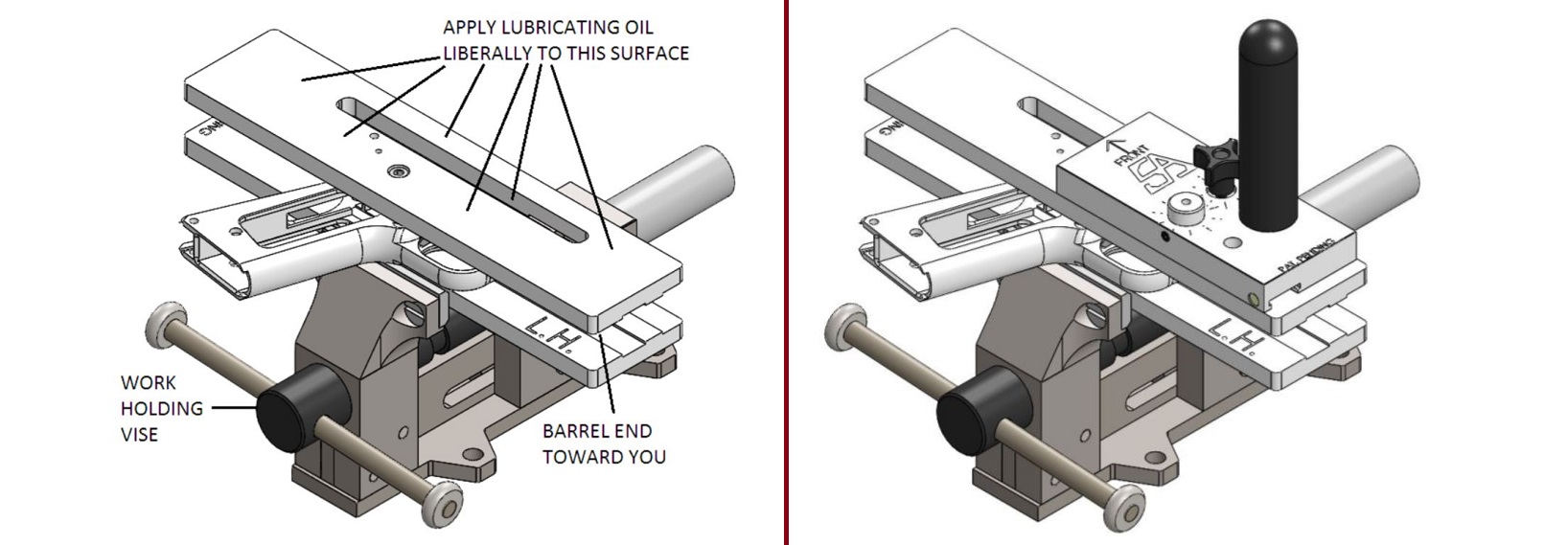

AR Jig Setup

This is how virtually all AR jigs will set up for work. A tabletop vise clamps the jig and 80% lower together vertically. Ideally, a cross-slide vise is used to make quick and precise lateral movements with the jig while milling. Once machining the cavity begins, the jig should not be moved or disassembled. Only the templates are swapped out to complete the cavity before drilling the receiver's pin holes. If you want to see exactly how an 80% lower is completed for an AR-15 build using this jig, check out the guide below:

Pistol Jigs

Popular handguns like the 1911, GLOCK series, and Sig P320 can now be built using 80% frames. To accommodate these builds, various 80% pistol jigs were developed. Like AR jigs, handgun jigs vary based on the make and model being built. They all allow the builder to perform these universal fabrication steps on the 80% frame in question:

- Cut the slide rails

- Cut the barrel seat

- Drill the parts kit's pin holes

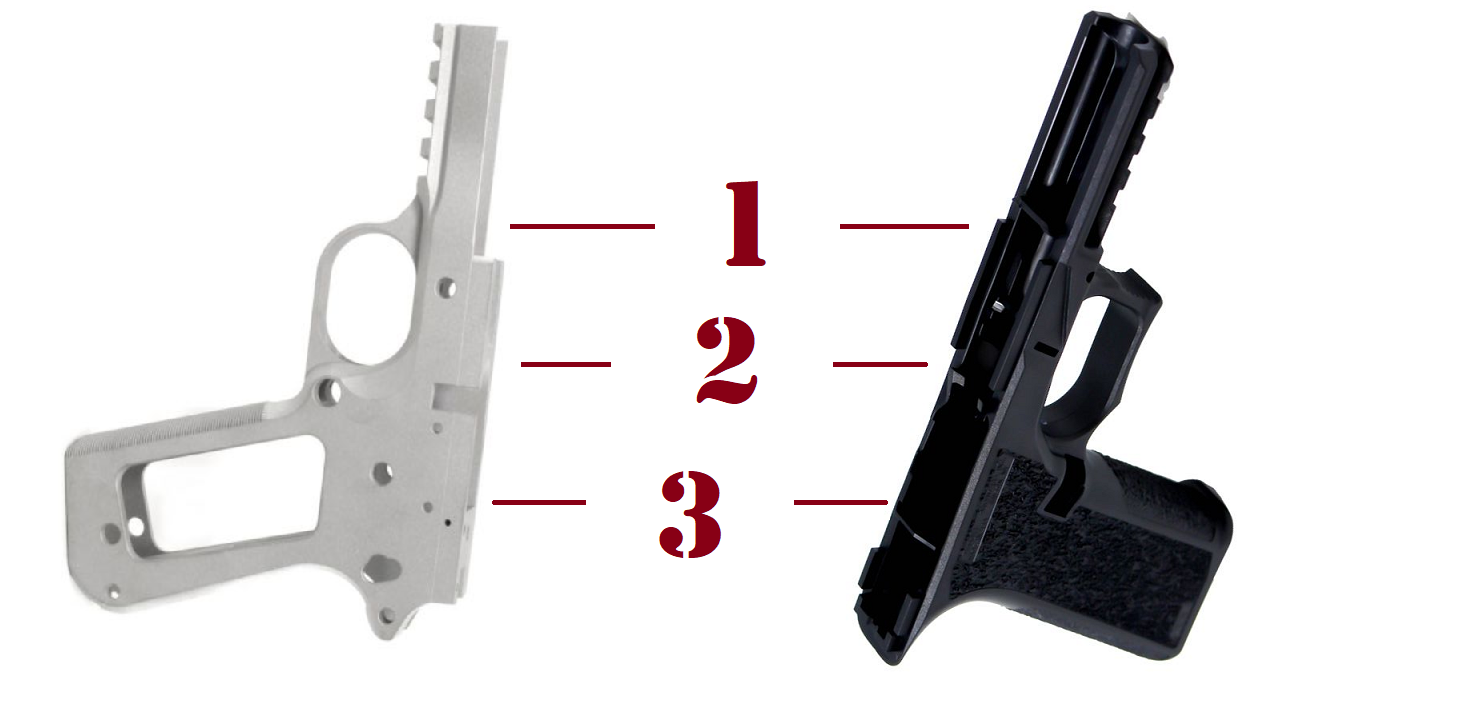

Pistol Jig Parts Diagram

Side Plates

Pistol jigs all use at least two side plates to secure the frame, like an AR jig does.

Cutting Templates

Unlike the AR's 80% lowers, there is no solid metal cavity that needs to be milled on an 80% frame. Instead, smaller amounts of material are carved out to make room for the slide and barrel. These fabrication requirements dictate how each pistol jig is made. On polymer frames, cutting the excess material is easy and requires just a few minutes with a pair of snips. So, a polymer handgun jig has a simple outline built into the side plates to show the builder where to cut. Aluminum frames (like the 1911's 80% frame) requires a bit more of a robust approach. A hand cutting tool is provided with carbide blades. On other 80% frames, instructions will indicate where the builder must use a Dremel or cutting wheel.

Drill Bits

80% frames don't require end mill bits for cutting. So, pistol jigs only come with drill bits based on the handgun's required pin holes.

Pistol Jig Setup

The pistol jig setup is simpler than the typical AR jig, especially if you're fabricating a polymer frame. This jig provides all the templates and guides for completing the frame inside: It has pre-drilled guide holes for the pin hole locations located on the side plates, and the recessed areas atop each plate indicate where to trim excess material for the slide rails. Inside, a guide shows how to shape the barrel seat. It will be secured vertically in a tabletop vise for machining.

See how to complete a polymer pistol frame here.

Completing the 1911 or Sig P320 frame requires a metal jig and more powerful cutting equipment, but the process for completing the frame is still largely the same. Slide rails and the barrel seat must be cut. In this case, the cutting tool is shown above, riding along the template in the side plate. Pin holes are guided via the jig and drilled through the frame for the trigger and other parts.

Here's how to complete the 1911 frame.

Frequent Questions

There are plenty of questions you probably have, and some you didn't think of. Here are the most common Q-&-A's.

Q: Are 80% jigs universal?

A: Yes and no. AR-type jigs are usually capable of completing more than one type of AR receiver. For example, most AR-15 jigs are also compatible with AR9 80% lowers for 9mm carbine builds, since the fire control cavity and exterior dimensions of the receiver are identical, except for the magazine well. The Stealth Arms 1911 jig works with both Government and Commander frames, but Polymer80's handgun jigs must be sized up with their corresponding frame size. It's best to check compatibility when ordering.

Q: Do disposable jigs work with other receivers?

A: Typically, yes. As long as the receiver the jig comes with uses the same dimensions and parts as other receiver or frame blanks. For example, Polymer80's AR-15 80% lower is identical in shape to a mil-spec lower, and its disposable jig could be used to fabricate an aluminum receiver.

Q: Is a jig legal to own?

A: Yes. Like an 80% lower, a jig is just another tool or part. It isn't considered a firearm or some type of "restricted" or special equipment. Jigs aren't regulated by the ATF, and it's completely legal to own one in all 50 states without any license or permit.

Q: Are jigs reusable?

A: Almost always, yes. Metal jigs are considered reusable and can fabricate multiple 80% lowers and frames. Polymer jigs are considered disposable, but they can be reused if the builder is careful not to damage the jig while using it for its first frame or lower.

Q: Are bits reusable?

A: Yes. Even when drilling and milling metal, any jig's bits should be capable of completing at least two, three, or more 80% receivers.

Q: How quickly does a jig work?

A: With the recommended tools, an 80% lower or frame can be completed in 15 to 30 minutes. New builders and folks using simpler tools (like a drill press instead of a mill) should expect to spend approximately 30 minutes to 1 hour completing a receiver. Whether building an AR or handgun, completing a polymer receiver takes about half as much time as completing an aluminum receiver.

Q: What other tools do I need?

A: Required tools depends largely on the type of lower or frame. You'll need a drill press or milling machine with cutting fluid to operate an AR jig. Pistol jigs require only a hand drill for completing the pin holes and cutting is accomplished using snips, a cutting tool that looks like a wood planer, or a Dremel or grinder.

Q: What other parts do I need to complete a firearm?

A: That depends. If you're finishing an AR-15 receiver, then you'll want to consider a rifle kit or pistol kit. These build kits include all other parts you need to finish your build, including the lower parts kit for your fresh receiver. For pistols, it's similar: Buy a pistol parts kit that's compatible with your frame.

DISCLAIMER: If you are new to the world of DIY gun building, you likely have a lot of questions and rightfully so. It’s an area that has a lot of questions that, without the correct answers, could have some serious implications. At GunBuilders.com, we are by no means providing this content on our website to serve as legal advice or legal counsel. We encourage each and every builder to perform their own research around their respective State laws as well as educating themselves on the Federal laws. When performing your own research, please be sure that you are getting your information from a reliable source.